Why Wespe

Wespe aims to the world’s best in MEA and stack for PEM water electrolysis. We research and develop together with our customers and do our best in even small things to provide you the value you want.

PEM Water Electrolysis Stack

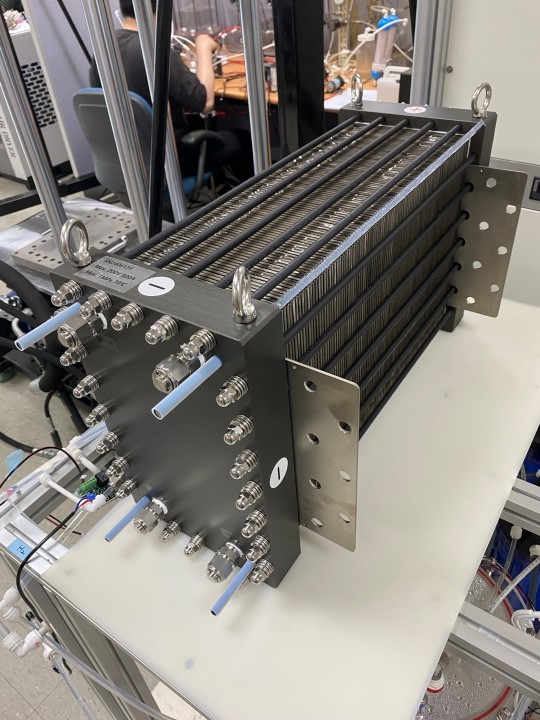

Photograph of active area 330㎠ 100-cell stack

| Number of Cells | 24 | 50 | 100 |

|---|---|---|---|

| Hydrogen Generation Rate (Nm3/hr) | 5.5 | 11.4 | 22.8 |

| H2 Purity | Higher than 99.99 % (except humidity) | ||

| H2 Pressure | ~ 10 bar | ||

| Stack Operation Temperature | Recommend 60 ~ 70 ˚C (5 ~ 90 ˚C possible) | ||

| Oxygen Generation Rate (Nm3/hr) | 2.7 | 5.7 | 11.4 |

| Maximum Applying Current (A) | 500 | 500 | 500 |

| Maximum Applying Voltage (V) | 48 | 100 | 200 |

| Maximum Power Consumption (kW) | 24 | 50 | 100 |

|

Water Consumption (L/hr) (assumed recycling water in H2 chamber) |

5 | 10 | 20 |

| Water Quality | Distilled or Deionized Water (lower than 1 mS/cm) | ||

| Fluid inlet & outlet connection | 3/8 inch NPT fitting | ||

|

Stack Dimension (W x H x D)mm (exclude bolt tips) |

218x385x225 | 218x385x350 | 218x385x590 |

| Weight (kg) | 50 | 70 | 110 |

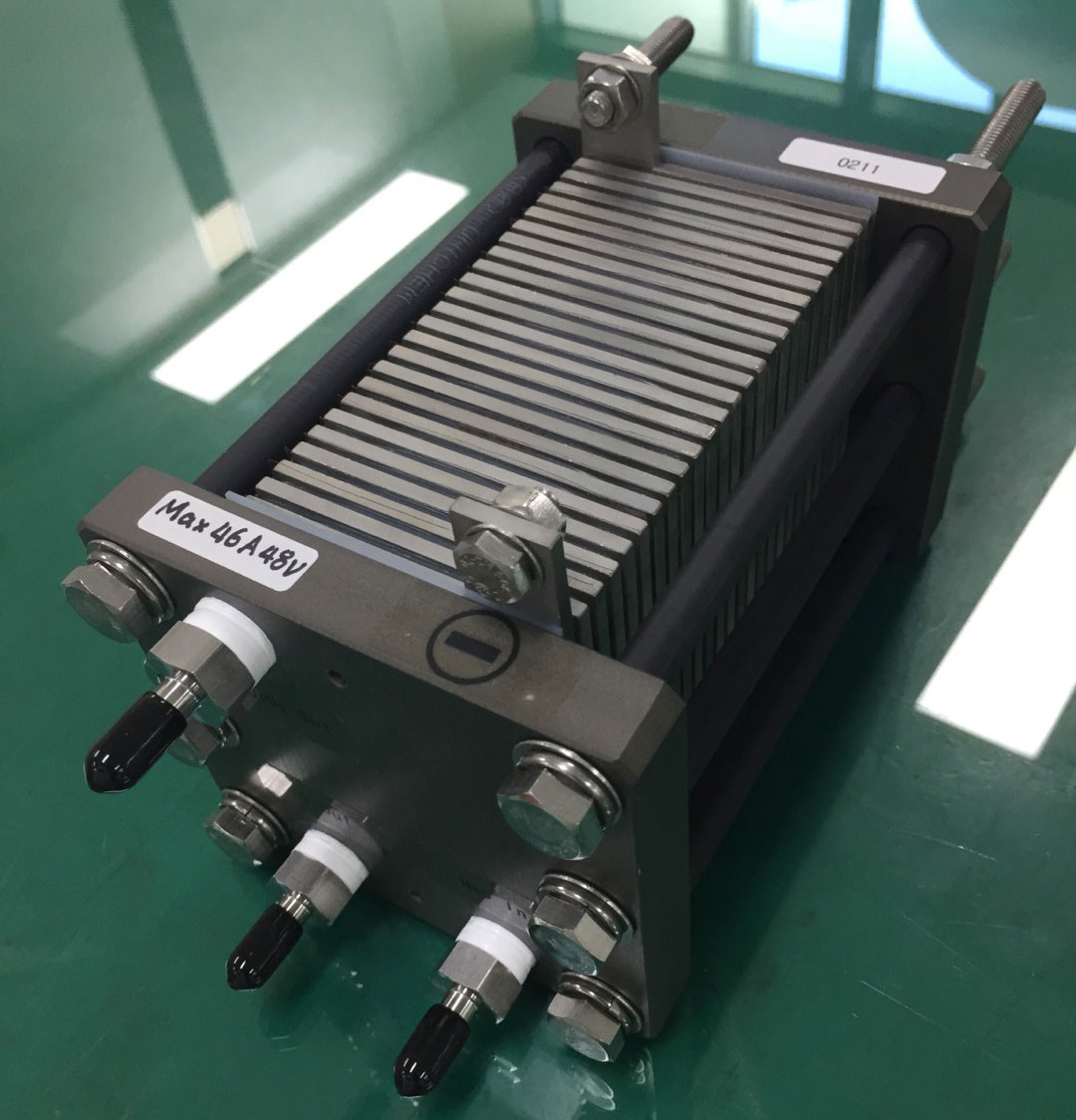

Photograph of active area 25㎠ 24-cell stack

| Number of Cells | 4 | 12 | 24 |

|---|---|---|---|

| Hydrogen Generation Rate (NL/hr) | 70 | 220 | 440 |

| H2 Purity | Higher than 99.99 % (except humidity) | ||

| H2 Pressure | ~ 3 bar | ||

| Stack Operation Temperature | Recommend 60 ~ 70 ˚C (5 ~ 90 ˚C possible) | ||

| Oxygen Generation Rate (NL/hr) | 35 | 110 | 220 |

| Maximum Applying Current (A) | 40 | 40 | 40 |

| Maximum Applying Voltage (V) | 8 | 24 | 48 |

| Maximum Power Consumption (W) | 320 | 960 | 1920 |

|

Water Consumption (cc/hr) (assumed recycling water in H2 chamber) |

60 | 180 | 360 |

| Water Quality | Distilled or Deionized Water (lower than 1mS/cm) | ||

| Fluid inlet & outlet connection | 1/4 inch NPT fitting | ||

|

Stack Dimension (W x H x D)mm (exclude bolt tips) |

100x90x55 | 100x90x95 | 100x90x155 |

| Weight (kg) | 1.5 | 2.1 | 3.0 |

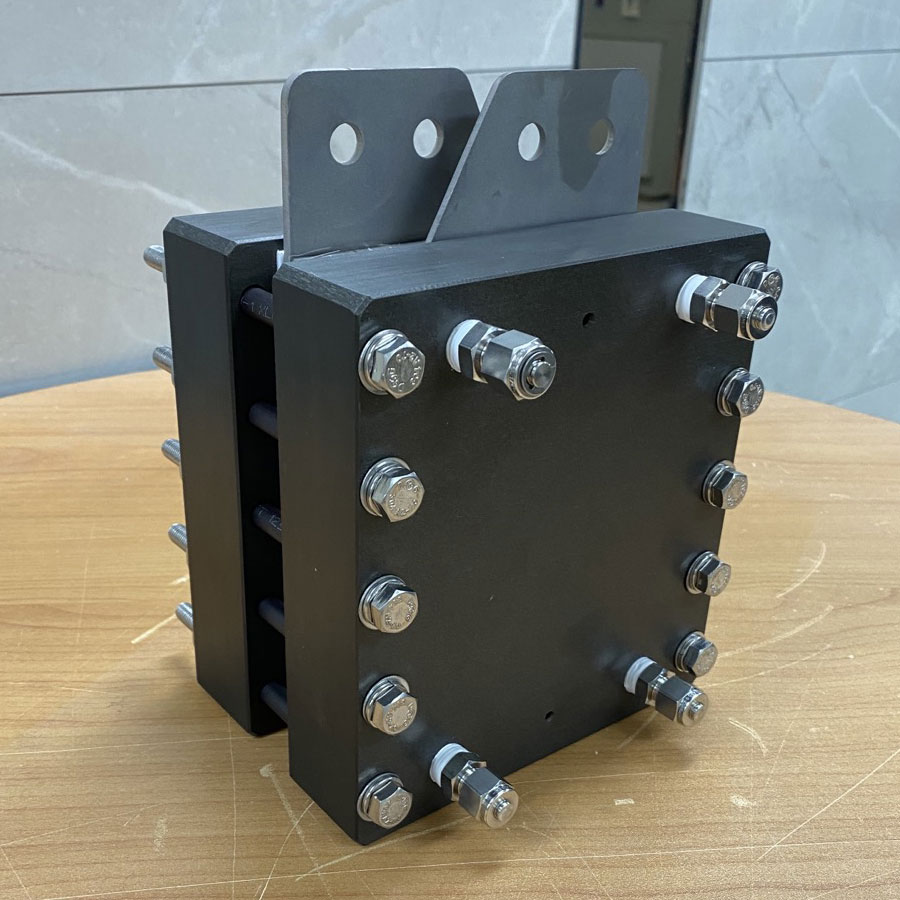

Photograph of active area 100㎠ 4-cell stack

| Number of Cells | 4 | 12 | 24 |

|---|---|---|---|

| Hydrogen Generation Rate (NL/hr) | 270 | 820 | 1640 |

| H2 Purity | Higher than 99.99 % (except humidity) | ||

| H2 Pressure | ~ 7 bar | ||

| Stack Operation Temperature | Recommend 60 ~ 70 ˚C (5 ~ 90 ˚C possible) | ||

| Oxygen Generation Rate (NL/hr) | 135 | 410 | 820 |

| Maximum Applying Current (A) | 150 | 150 | 150 |

| Maximum Applying Voltage (V) | 8 | 24 | 48 |

| Maximum Power Consumption (kW) | 1.2 | 3.6 | 7.2 |

|

Water Consumption (cc/hr) (assumed recycling water in H2 chamber) |

230 | 750 | 1500 |

| Water Quality | Distilled or Deionized Water (lower than 1 mS/cm) | ||

| Fluid inlet & outlet connection | 1/4 inch NPT fitting | ||

|

Stack Dimension (W x H x D)mm (exclude bolt tips) |

160x175x107 | 160x175x147 | 160x175x205 |

| Weight (kg) | 8.8 | 11.4 | 15.4 |

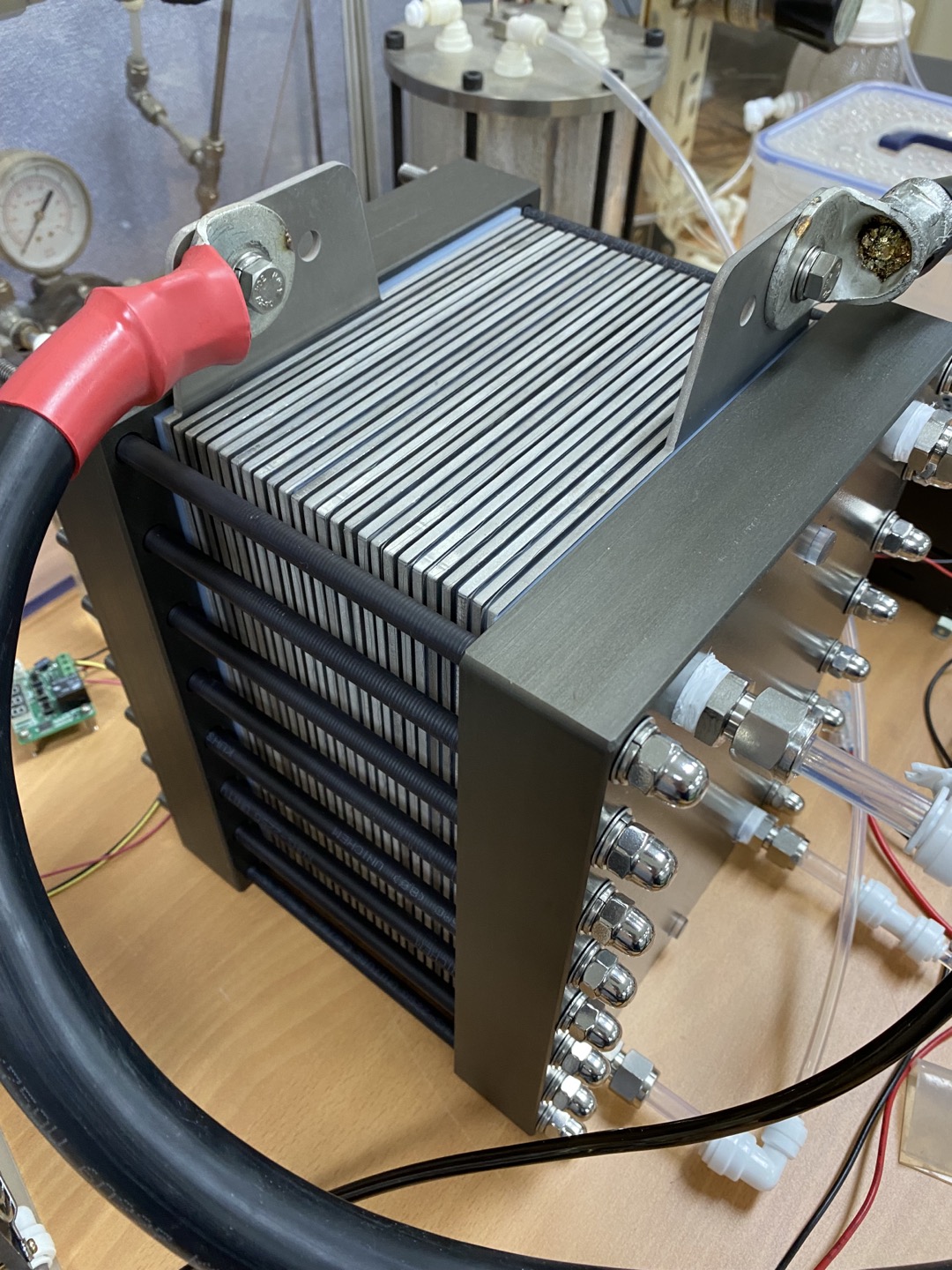

Photograph of active area 270㎠ 25-cell stack

| Number of Cells | 4 | 12 | 24 |

|---|---|---|---|

| Hydrogen Generation Rate (Nm3/hr) | 0.8 | 2.4 | 5 |

| H2 Purity | Higher than 99.99 % (except humidity) | ||

| H2 Pressure | ~ 7 bar | ||

| Stack Operation Temperature | Recommend 60 ~ 70 ˚C (5 ~ 90 ˚C possible) | ||

| Oxygen Generation Rate (Nm3/hr) | 0.4 | 1.2 | 2.5 |

| Maximum Applying Current (A) | 400 | 400 | 400 |

| Maximum Applying Voltage (V) | 8 | 24 | 48 |

| Maximum Power Consumption (kW) | 3.2 | 9.6 | 19.2 |

|

Water Consumption (L/hr) (assumed recycling water in H2 chamber) |

0.6 | 2.0 | 4.0 |

| Water Quality | Distilled or Deionized Water (lower than 1 mS/cm) | ||

| Fluid inlet & outlet connection | 3/8 inch NPT fitting | ||

|

Stack Dimension (W x H x D)mm (exclude bolt tips) |

214x306x107 | 214x306x147 | 214x306x205 |

| Weight (kg) | 18 | 24 | 31 |

Wespe aims to the world’s best in MEA and stack for PEM water electrolysis. We research and develop together with our customers and do our best in even small things to provide you the value you want.